Schaeffler expands aftermarket range of innovative thermal management modules

Date: Thursday 30 June 2022

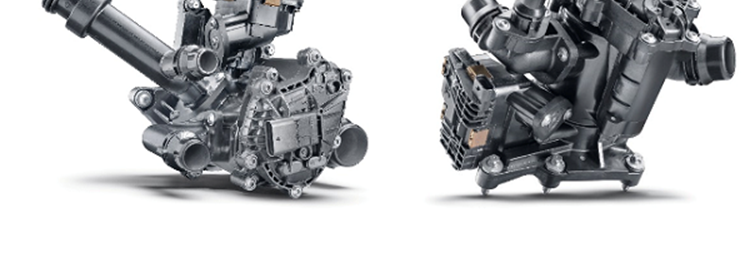

The Aftermarket division of the global industrial and automotive supplier Schaeffler is expanding its range of thermal management modules (TMM) under the INA brand. Schaeffler has supplied these innovative bolt-on systems for original fitment since 2011, when the first-generation TMM was launched. Working closely with leading vehicle producers, Schaeffler designs and manufactures TMMs that are capable of accurately controlling the temperature in all cooling circuits as required, which allows the engine to reach its optimum operating temperature quicker and more efficiently. This leads to an increase in driving comfort is increased, whilst fuel consumption and CO2 emissions are reduced. Since its launch, TMM technology has been continuously updated to ensure that it continues to meet the increasing demands of the latest high-performance hybrid engines. The latest Generation 2 TMMs are now available as INA complete repair solutions, and sold exclusively by Schaeffler in the independent aftermarket.

Second generation thermal management modules

Generation 2 TMM technology is still based on rotary slide valves that control the coolant flow depending on the driving situation, but the latest actuator design achieves significant improvements in functionality by using the two rotary slide valves independently. One valve is responsible for controlling the flow of coolant to and from the radiator, while the other separates the engine cooling circuits in the cylinder head and block. This makes it possible to create what Schaeffler calls a "split cooling" concept.

‘Split cooling’ successfully copes with the increased demands from start-stop or hybrid operation, ensuring efficient and accurate temperature control in the cylinder head and block through more targeted cooling. Frictional power in the combustion chambers significantly reduces when switching from pure electric mode and during the longer resting phases caused by the start-stop function. This leads to an optimal combustion process, reduced wear and lower CO2 emissions.

"Thermal management systems play a central role in improving energy efficiency and reducing CO2 emissions. The precision-tuned, intelligent control of increasingly complex cooling and heating circuits ensures that all relevant systems operate within the optimum temperature range at all times. This helps protect the environment whilst also increasing the service life of the components. In line with global car parc development, we are constantly developing our thermal management product range, and we are proud to be the first supplier in the aftermarket to offer the latest Generation 2 TMM repair solutions for hybrid vehicles," explained Maik Evers, Head of Product Management at Schaeffler Automotive Aftermarket.

Range expansion: latest repair solutions for BMW and MINI

Schaeffler has exclusively offered Volkswagen Audi Group TMMs to the independent aftermarket for some time. The range has now been extended to include two new part numbers for BMW and MINI engines: part number 538 0810 10 for 3- and 4-cylinder engines (B38 and B48) and part number 538 0811 10 for 6-cylinder engines (B58). These two references cover a car parc of over two million vehicles, which is set to double during the next three years.

Photo: Schaeffler

Information on Schaeffler products, fitting instructions, labour times and much more can be found on the REPXPERT workshop portal – www.repxpert.co.uk – the REPXPERT app, or by calling the Schaeffler REPXPERT hotline on 0872 737 0037.